Struggling to connect with good factories? Wasting time with unresponsive or low-quality suppliers is frustrating. Learn the right approach to find reliable partners efficiently.

Contact reliable manufacturers by preparing clear information (tech packs!), researching their specialty, writing professional emails, and being ready to discuss details like MOQ, samples, and quality expectations. Professionalism is key.

Finding the right factory is just the start. Knowing how to make that first contact effectively makes a huge difference. Let's look at the first step: the email.

How do I write an email to a clothing manufacturer?

Are your emails to factories getting ignored? Unclear messages waste everyone's time and cost you opportunities. Write emails that get noticed and get results.

Write a clear subject line (e.g., "Inquiry: Hoodie Production - [Your Brand Name]"). Introduce your brand briefly. Clearly state what you need (item, quantity, target quality). Attach a tech pack if possible. Ask specific questions (MOQ, lead time).

!

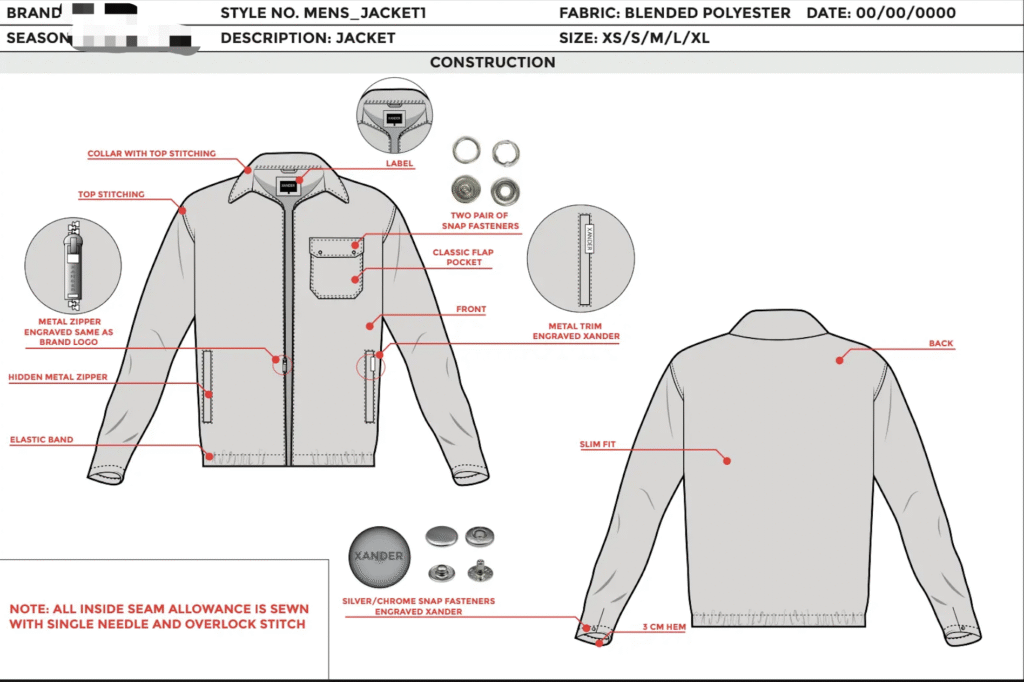

From my side, receiving a clear, professional email makes a huge difference. It shows you're serious and prepared. Vague emails asking "how much for hoodie?" are impossible to answer properly and often get overlooked when we are busy. You need to provide enough detail for us to give you a meaningful response. A good Tech Pack is gold – it should include detailed sketches, measurements, fabric specifications, construction details, colors, and logo/print placement. My client, Fifty Fifty, sends detailed tech packs now, and it makes quoting faster and more accurate for their complex hoodies. Here’s what a strong first email includes:

| Email Section | Purpose | What to Include |

|---|---|---|

| Subject Line | Get noticed, easy to categorize | Clear & Specific: "Inquiry: Custom Hoodie Order - [Your Brand Name]" |

| Introduction | Who are you? | Briefly introduce your brand and what you do (e.g., UK-based streetwear brand). |

| Product Details | What do you want made? | Specify garment type (hoodie, t-shirt), attach tech pack or detailed sketches. |

| Quantity | How many? | Give an estimated order quantity per style/color (e.g., 300 hoodies, 3 colors). |

| Quality Target | What level are you aiming for? | Mention target market/quality level (e.g., premium streetwear, mid-range). |

| Specific Questions | What info do you need now? | Ask about Minimum Order Quantity (MOQ), estimated lead time, sample process. |

| Call to Action | What's the next step? | Ask if they can produce this style and request a quote or further discussion. |

Be polite and professional. Show you've done some basic research on their factory if possible (e.g., "I saw on your website you specialize in quality hoodies"). This effort stands out.

How do I partner with a clothing manufacturer?

Thinking of your manufacturer as just an order-taker? This mindset leads to problems down the line. Build a strong partnership for long-term success.

Partner by communicating openly and often. Understand their process. Respect their expertise. Provide clear feedback. Pay on time. Discuss quality control together. Think long-term, not just one order. Treat them like a valued part of your team.

A true partnership goes far beyond just placing orders. It's about building a relationship based on trust, communication, and mutual understanding. This is especially important when dealing with complex products like the streetwear we produce at Adiwe. A transactional approach – just sending an order and expecting perfect results – often leads to disappointment. For example, Fifty Fifty needed a manufacturer who could truly understand and execute their complex designs, not just take an order. They needed a partner. Building this takes effort from both sides. It starts with clear agreements, often outlined in a manufacturing contract covering terms, quality standards, and timelines. Regular communication is vital – not just emails, but sometimes video calls to discuss samples or solve problems quickly. Visiting the factory (if possible) builds immense trust. Providing constructive feedback on samples helps us improve and meet your vision. Equally, listening to our feedback is important – we might suggest a better fabric or construction method based on our experience. Paying invoices promptly according to the agreed terms is fundamental. Ultimately, a partnership means viewing your manufacturer as an extension of your own team, working together towards the shared goal of creating amazing products for your customers.

How do I talk to manufacturers?

Afraid of saying the wrong thing to your manufacturer? Miscommunication causes costly mistakes and delays. Learn how to talk effectively for smoother production.

Talk clearly and simply. Be prepared with details (tech packs!). Use visuals if needed. Ask direct questions. Listen to their feedback and expertise. Be respectful of their time and process. Confirm understanding to avoid errors.

Effective communication is probably the most critical factor for success once you've found a potential manufacturing partner. From my perspective as a factory owner, the best conversations happen when the brand is prepared. Having your tech packs ready, knowing your quantities, and having clear quality expectations makes everything smoother. Use simple, direct language. Avoid slang or overly technical jargon unless you are sure everyone understands it. English is common in international business, but keeping sentences clear helps bridge any potential language gaps. Don't be afraid to use visuals – photos, detailed sketches, or even short videos can explain complex details much better than words alone. When discussing issues or giving feedback, be specific and constructive. Instead of saying "I don't like it," explain why – "The stitching on the pocket is uneven," or "This fabric feels thinner than the sample." Ask direct questions and make sure you understand the answers. It's always good practice to summarize key points and decisions at the end of a conversation or in a follow-up email to ensure everyone is on the same page. Remember, manufacturers are experts in production; listen to their suggestions regarding feasibility or potential improvements. Respecting their time and expertise builds a much better working relationship.

Conclusion

Clear communication, professional emails, and building real partnerships are key to contacting and working successfully with reliable clothing manufacturers like us at Adiwe.