Are you struggling to find clothes that truly represent your brand's unique style? Tired of generic options that don't capture your vision? Custom clothing manufacturing is the solution you need.

Custom clothing manufacturing is the process where a factory, like mine at Adiwe, creates garments specifically based on a client's unique designs, specifications, fabrics, and branding requirements, rather than producing standardized items.

Understanding custom manufacturing is the first step for brands wanting truly unique apparel. But how does this process actually unfold from your idea to a finished product? Let's dive deeper into what makes custom production work and why it matters for brands like yours.

What is a custom manufacturing process?

Confused about turning your designs into actual clothing? The custom manufacturing journey can seem complicated, leaving you unsure where to even begin. We make it clear and manageable.

The custom manufacturing process typically involves several key stages: design consultation, tech pack development, material sourcing, pattern making, sample creation, bulk production, quality control checks, and final shipment.

!

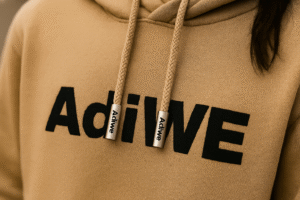

Let's break down how we bring your vision to life here at Adiwe. It's more than just sewing; it’s a partnership to create exactly what you need. I've worked with many brands, like "Fifty Fifty" from England, who need precise execution of complex designs.

The Journey from Idea to Garment

The process starts with your idea. We discuss your design concepts, target audience, and desired features during the consultation phase. Then comes the crucial tech pack. This is the blueprint for your garment, detailing everything: measurements, materials, colors, stitching, logo placement, and any special techniques. A clear tech pack prevents misunderstandings later. I always emphasize getting this right because it saves time and money.

Next is material sourcing. We help find the perfect fabrics and trims based on your quality needs, budget, and design. After that, our experts create patterns and sew the first sample. You review this sample to check fit, quality, and details. We make adjustments based on your feedback until you approve it. Once the sample is perfect, we move to bulk production on our dedicated lines. Rigorous quality control happens throughout production, not just at the end. Finally, we handle packing and shipping to get your finished order to you.

| Stage | Key Activity | Why It's Important |

|---|---|---|

| Consultation & Design | Discussing ideas, sketches, requirements | Aligning vision and feasibility |

| Tech Pack Creation | Creating detailed technical specifications | The essential blueprint for production |

| Material Sourcing | Selecting fabrics, trims, accessories | Defining quality, look, and feel |

| Pattern & Sampling | Creating patterns and sewing a prototype sample | Verifying fit, design, and construction |

| Sample Approval | Client review and feedback | Ensuring satisfaction before bulk |

| Bulk Production | Manufacturing the order quantity | Efficiently creating the garments |

| Quality Control | Inspections at multiple stages | Maintaining standards, reducing errors |

| Packing & Shipping | Folding, tagging, packing, and logistics | Delivering the final product correctly |

What does custom-made clothing mean?

Hearing the term "custom-made" but not sure exactly what it means for your brand? Worried it's just a fancy term without real benefits? It actually means complete control over your product.

Custom-made clothing means garments designed and produced exclusively for one specific client according to their unique requirements. It's not off-the-shelf; it reflects the client's brand identity through personalized design, fit, fabric, and details.

This is very different from other ways of getting clothing made. For brands aiming for a unique market position, understanding this difference is vital. Let's look at what truly sets custom-made apart and why it's often the best choice for serious brands.

Defining "Custom-Made"

Think of it like ordering a tailored suit versus buying one off the rack. Custom-made clothing is built from the ground up based on your specific instructions. This includes:

- Unique Designs: Your specific patterns, cuts, and styles that aren't available elsewhere.

- Specific Fabrics: You choose the exact material, weight, color, and finish. We source it for you.

- Personalized Fit: Graded sizing based on your target customer's measurements.

- Branded Details: Custom labels, tags, buttons, zippers, prints, or embroidery unique to your brand.

Key Differences from Other Models

It's important not to confuse custom-made with private label or white label.

- Private Label: A factory produces existing styles, and you put your brand label on them. The design is theirs, not yours.

- White Label: Similar to private label, these are generic products ready for branding.

- Custom-Made: The design, materials, and details are all dictated by you, the client. We, the manufacturer, bring your unique vision to life.

Why Choose Custom?

For brands like the ones I work with in North America and Europe, custom manufacturing is essential. It solves problems like the one my client "Fifty Fifty" faced: finding manufacturers who can accurately replicate complex streetwear designs with specific craftsmanship. Custom allows for:

- Brand Differentiation: Stand out with unique products nobody else has.

- Targeted Quality: Control the materials and construction to meet your exact quality standards.

- Exclusivity: Build a loyal following around unique apparel.

- Precise Execution: Get complex designs made correctly, ensuring your vision is realized.

At Adiwe, our focus on top quality, personalized design, and handling complex craftsmanship makes us a strong partner for custom projects.What is the meaning of clothing manufacturing?

Do you think clothing manufacturing is simply about sewing machines? It's a complex global industry, and misunderstanding its scope can impact your brand's success and sourcing decisions.

Clothing manufacturing is the comprehensive industrial process of converting raw materials like fabrics, threads, and accessories into finished garments through organized systems involving design interpretation, cutting, sewing, finishing, quality control, and logistics on a significant scale.

Knowing what's involved helps you choose the right partners and manage production effectively. It’s a detailed operation requiring expertise at every stage, much more than just operating sewing machines. Let's explore the different facets of this industry.The Scope of Production

Clothing manufacturing involves many steps beyond just assembling pieces:

- Pre-production: Includes pattern making, grading (creating different sizes), marker making (planning fabric layout for efficient cutting), and sourcing all materials.

- Cutting: Laying out fabric layers and precisely cutting pattern pieces using manual or automated methods. Accuracy here is critical.

- Sewing/Assembly: Stitching the cut pieces together using various specialized machines. This is where the garment takes shape.

- Printing/Embroidery: Applying graphics, logos, or decorative elements if required by the design.

- Finishing: Includes washing (if needed), pressing/ironing, attaching buttons, trimming loose threads, final quality checks, folding, and tagging.

- Packing & Logistics: Preparing garments for shipment according to client specifications.

Manufacturing Models

There are different approaches:

- Mass Production: Making large quantities of standardized items, often focused on low cost. Think fast fashion.

- Custom Manufacturing (like Adiwe): Producing goods based on specific client orders, often in smaller batches (though we handle large custom orders too), focusing on unique designs and higher quality control. This is typical for B2B wholesale serving specific brands.

Choosing Your Partner

Understanding manufacturing helps you evaluate potential factories. You need a partner who aligns with your needs. Key factors include:

- Expertise: Can they handle your specific type of garment (e.g., complex streetwear hoodies)?

- Quality Systems: Do they have robust quality control processes? We check quality constantly.

- Capacity: Can they handle your order volume (Minimum Order Quantities - MOQs) and meet deadlines? Our 5 production lines offer flexibility.

- Communication: Is it easy to communicate requirements clearly? This is vital, especially for international clients.

- Compliance & Ethics: Do they follow labor laws and ethical standards?

As a factory owner (Sunny from Adiwe), I know that successful manufacturing is built on trust, clear communication, and a commitment to quality from start to finish.Conclusion

Custom clothing manufacturing lets brands create unique apparel. It involves a detailed process from design to delivery, ensuring garments match your exact vision. Adiwe specializes in this partnership.