Finding the right factory for your custom streetwear in China feels impossible sometimes. You worry about quality, communication, and if they can truly capture your unique brand vision.

Identifying the best custom streetwear manufacturers in China involves focusing on their specialization in streetwear, proven customization capabilities, quality control systems, communication clarity, and reliability, rather than just size or location. A good fit meets your specific brand needs.

Here at Adiwe, based in China, I've seen countless brands navigate this search. We work as a B2B wholesale partner, specializing in top-quality, custom streetwear like hoodies and t-shirts for clients mainly in North America and Europe. Many brands, especially trend-focused ones or KOLs, need more than just a factory; they need a partner who understands design intricacy and quality demands. Let's break down some common questions buyers have when looking for manufacturers like us.

Who is the Biggest Apparel Manufacturer in China?

Thinking bigger is always better when choosing a manufacturer? Be careful, the largest factories often cater to huge global brands and might not suit your custom streetwear needs.

Shenzhou International Group Holdings Limited is often cited as China's largest apparel manufacturer, particularly in vertically integrated knitwear. However, they primarily serve giants like Nike and Adidas, often unsuitable for smaller custom streetwear brands needing flexibility.

!

Diving Deeper into Manufacturer Size

What does "biggest" really mean in apparel manufacturing? It usually refers to:

- Production Capacity: The sheer volume of garments they can produce annually.

- Revenue: Their total sales figures.

- Employee Count: The number of workers they employ.

- Vertical Integration: Owning multiple stages of production, from fabric milling to garment assembly.

Shenzhou International: A Profile

Shenzhou is massive by all these metrics. They operate huge facilities, employ tens of thousands, and work directly with the world's largest sportswear and fashion brands. Their scale allows for immense efficiency and cost control on massive orders of relatively standardized products (even with brand variations).

Why Biggest Isn't Always Best for Custom Streetwear

For brands needing highly customized, trend-driven streetwear, especially those not ordering hundreds of thousands of units per style, the "biggest" factory often presents challenges: - Minimum Order Quantities (MOQs): Mega-factories typically have very high MOQs, far beyond the needs of emerging brands or specialized collections.

- Flexibility: Their systems are optimized for volume, making them less agile for complex, small-batch custom designs requiring unique techniques or frequent changes. Clients like Fifty Fifty, who need intricate designs reproduced perfectly, often find smaller, specialized factories more responsive.

- Focus: Their primary attention is on their multi-million dollar clients. Smaller brands might not get the dedicated service or design input needed.

The 'Best Fit' Approach

Instead of seeking the "biggest," focus on the "best fit." This means finding a manufacturer whose capabilities, quality level, communication style, and business model align with yours. Medium-sized, specialized factories like Adiwe often provide the ideal balance. We have the capacity for wholesale orders (5 production lines) but retain the flexibility and expertise for high-customization streetwear, understanding the nuances of trendy designs, specific fabrics, and detailed craftsmanship required by brands targeting markets like North America and Europe.

| Factor | Mega-Factory (e.g., Shenzhou) | Specialized Factory (e.g., Adiwe) | Which is Better for Custom Streetwear? |

|---|---|---|---|

| Typical Client | Global Giants (Nike, Adidas) | Trend Brands, KOLs, Smaller Labels | Specialized Factory |

| MOQs | Extremely High | Moderate, More Flexible | Specialized Factory |

| Customization | Less Flexible, Standardized Focus | High Flexibility, Focus on Unique Designs | Specialized Factory |

| Service Focus | Geared towards Volume Clients | Personalized Attention, Design Input | Specialized Factory |

| Expertise | Mass Production Efficiency | Niche Trends, Complex Craftsmanship | Specialized Factory |

The key takeaway is that scale doesn't equal suitability, especially in the dynamic world of custom streetwear.

Where is the Best Place to Manufacture Clothing in China?

China is huge, and picking the wrong region can cause headaches. Manufacturing location impacts logistics, costs, and access to specific skills or materials needed for your garments.

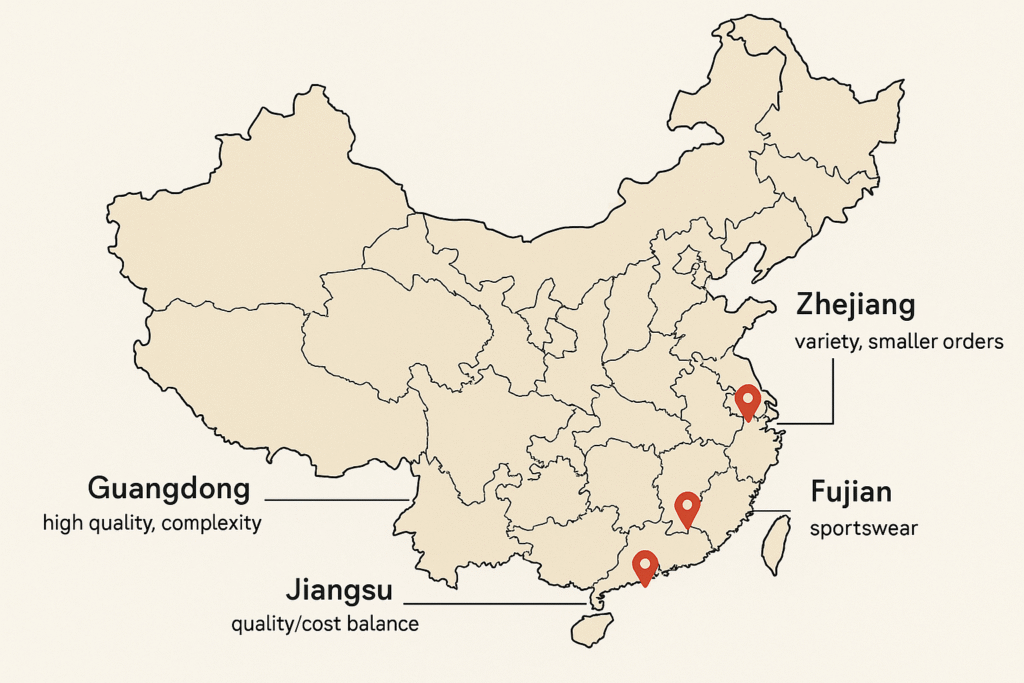

Key manufacturing hubs include Guangdong (Pearl River Delta) for high quality and complexity, Zhejiang for variety and smaller orders, Jiangsu for balanced quality/cost, and Fujian for sportswear. The "best" place depends on your specific product and priorities.

Diving Deeper into China's Manufacturing Hubs

Choosing the right region is crucial for sourcing success. As someone running a factory (Adiwe) focused on exporting high-quality streetwear, location matters for supply chain, talent, and logistics. Here’s a breakdown of major areas:

- Guangdong Province (Pearl River Delta - Guangzhou, Dongguan, Shenzhen):

- Pros: Considered the powerhouse for higher-quality and complex garments. Excellent access to skilled labor, advanced manufacturing techniques, vast fabric and accessory markets (like the Guangzhou Zhongda Market). Proximity to major ports (Shenzhen, Guangzhou, Hong Kong) is a huge plus for export-focused brands like my clients in North America and the UK. This area is strong in handling intricate designs, washes, and finishes common in trendy streetwear.

- Cons: Labor and manufacturing costs tend to be higher than in other regions.

- Best for: Brands prioritizing quality, complex designs, specialized techniques, and reliable export logistics. This is where factories focusing on premium custom streetwear are often found.

- Zhejiang Province (Ningbo, Yiwu, Hangzhou):

- Pros: Known for incredible variety, especially commodity items. The Yiwu market is world-famous for sourcing trims, accessories, and ready-made goods. Generally offers lower MOQs and competitive pricing. Strong in knitwear and sweaters.

- Cons: Quality can be highly variable. May lack the deep specialization in high-fashion or complex streetwear found in Guangdong. Requires careful vetting.

- Best for: Brands needing huge variety, smaller order quantities, or sourcing basic items and accessories.

- Jiangsu Province (Suzhou, Wuxi, Nanjing):

- Pros: Strong textile industry base, offering a good balance between quality and cost. Well-developed infrastructure. Good for woven garments and silk products.

- Cons: Perhaps less known specifically for the cutting-edge trend aspect of streetwear compared to Guangdong.

- Best for: Brands looking for a mid-point in cost and quality, particularly for woven goods or items requiring specific textile expertise.

- Fujian Province (Quanzhou, Xiamen):

- Pros: A major hub for sportswear, athletic shoes, and outerwear. Strong capabilities in performance fabrics and related manufacturing techniques.

- Cons: Less focused on general fashion or the specific niche of highly customized fashion streetwear compared to Guangdong.

- Best for: Sportswear brands, performance apparel, jackets, and footwear.

| Region | Key Strengths | Potential Weaknesses | Ideal Streetwear Type |

|---|---|---|---|

| Guangdong | High Quality, Complex Designs, Skilled Labor, Ports | Higher Costs | Premium Hoodies, Tees, Complex Graphics |

| Zhejiang | Variety, Lower MOQs, Accessories, Knitwear | Variable Quality | Basics, Knit Items, Accessories |

| Jiangsu | Balanced Cost/Quality, Textiles, Wovens | Less Streetwear Trend Focus | Woven Jackets, Shirts |

| Fujian | Sportswear, Shoes, Outerwear, Performance | Less Fashion Streetwear Focus | Athletic Hoodies, Jackets, Sneakers |

For Adiwe, being positioned to leverage the strengths needed for top-quality, trend-focused streetwear (implying a location likely benefiting from Guangdong's ecosystem) allows us to serve demanding clients effectively. Your "best" place depends entirely on balancing quality needs, product type, budget, and logistical requirements.

How Many Clothing Manufacturers are There in China?

Feeling overwhelmed by the sheer number of potential suppliers in China? Trying to count them all is exhausting and doesn't help you find the right one for your brand.

Estimates vary widely, from tens of thousands to over 100,000 clothing manufacturers in China, including everything from small workshops to giant factories. The exact number isn't as important as finding a reliable partner that meets your specific needs.

Diving Deeper into the Manufacturing Landscape

Trying to pin down an exact number of clothing factories in China is incredibly difficult. Here's why:

- Definitions Vary: What counts as a "manufacturer"? Does it include tiny family-run workshops, medium-sized specialized factories, huge conglomerates, or trading companies that outsource production?

- Registration Flux: Businesses open and close constantly. Official registration numbers might not capture the full picture, especially smaller operations.

- Informal Sector: A significant portion of manufacturing, particularly for simpler items or domestic markets, happens in less formalized settings.

Types of "Manufacturers" You Might Encounter:

Understanding the different types helps navigate the options:- Large Integrated Factories: Like Shenzhou, focused on massive volume for global brands. (Few in number, high barrier to entry).

- Medium-Sized Specialized Factories: These often focus on specific product types (like streetwear, knitwear, outerwear) or quality tiers. They offer a balance of capacity, flexibility, and expertise. This is where factories like Adiwe typically fit, catering to B2B wholesale for brands needing customization and quality.

- Small Factories/Workshops: Often family-run or with fewer employees. Can be very specialized and flexible with low MOQs, but quality control, capacity, and communication might be challenging for international clients.

- Trading Companies: These companies don't own factories but act as intermediaries. They manage communication and production with multiple factories. Can be convenient but adds a layer (and cost) and potentially less direct control over production.

Focus on Finding the Right Fit, Not Counting

The sheer number highlights the opportunity but also the challenge. Instead of getting lost in the numbers, focus your energy on defining your requirements and finding partners who meet them. I always advise clients like Fifty Fifty to prioritize factors like:

- Proven expertise in their specific product (e.g., complex hoodies).

- Demonstrable quality control processes.

- Clear communication and understanding of design details.

- Reliable production lead times.

- Fair pricing relative to the quality and service.

- Compliance with any required standards (social, environmental, safety).

Finding 5-10 potential good fits through platforms like Alibaba, attending trade shows (like Canton Fair), or using sourcing agents is far more valuable than knowing there are 50,000 factories you could work with. Vetting those potential partners thoroughly through samples, factory visits (if possible), and clear requirement setting is key.

Finding Your Top 10: It's About Fit, Not Just a List?

Searching for a definitive "Top 10" list online might seem helpful, but it's often misleading. The "best" manufacturer for one brand might be a terrible fit for another. What truly matters is finding the factories that align perfectly with your specific needs for custom streetwear. Instead of a generic list, let's focus on the criteria you should use to build your own shortlist of top potential partners.

Here’s what I consider essential when evaluating manufacturers for high-quality custom streetwear, based on my experience at Adiwe serving demanding brands:

- Streetwear Specialization: Do they truly understand streetwear aesthetics, fits, and trends? Look at their existing work and client base. Generic apparel factories might not grasp the nuances.

- Customization Capability: This is non-negotiable. Can they handle your specific needs?

- Fabrics: Offer variety, source specific materials, advise on suitability?

- Designs: Execute complex cuts, patterns, and constructions accurately? (Critical for clients like Fifty Fifty).

- Graphics & Logos: Master techniques like screen printing, DTG, puff print, complex embroidery, appliqué?

- Washes & Finishes: Achieve specific vintage looks, pigment dyes, or other treatments?

- Accessories: Provide custom labels, tags, drawstrings, zippers?

- Quality Control Systems: How do they ensure consistency and meet your standards? Ask about their QC process, checkpoints, and if they welcome third-party inspections. Top quality is crucial for brands exporting to discerning markets like North America and Europe.

- Communication: Is their team responsive? Do they understand English well (or have dedicated English-speaking staff)? Can they interpret technical packs and provide constructive feedback? Miscommunication is a major source of errors.

- MOQs (Minimum Order Quantities): Do their minimums align with your business model and order volume? Some factories specialize in huge runs, others are more flexible. As a B2B wholesale provider, Adiwe aims for MOQs that work for serious brands but might be higher than tiny startups require.

- Pricing & Value: Is the pricing competitive for the level of quality and service offered? The cheapest option is rarely the best value, especially for custom work demanding high quality.

- Reliability & Lead Times: Do they have a track record of delivering on time? Ask for realistic production timelines and factor in shipping.

- Compliance & Ethics: Do they meet any necessary social compliance standards (like BSCI or SEDEX) or environmental certifications if these are important to your brand values?

How Adiwe Measures Up (As an Example):

We built Adiwe specifically to excel in these areas for streetwear brands:- Focus: 100% on trendy, custom streetwear (hoodies, tees, etc.).

- Customization: Deep expertise in personalized design, fabrics, logos, and complex craftsmanship.

- Quality: Top-tier materials and construction are standard for our export clients.

- Communication: Dedicated team focused on understanding client needs.

- Model: B2B wholesale, geared towards established brands and KOLs.

Your Action Plan: Use these criteria as a checklist when researching and contacting potential manufacturers. Create your Top 10 list based on who best matches your unique requirements.

| Criteria | Key Question | Why it Matters for Custom Streetwear |

|---|---|---|

| Specialization | Do they know streetwear? | Ensures understanding of fit, trends |

| Customization Ability | Can they make your unique product? | Core requirement for differentiation |

| Quality Control | How do they guarantee quality? | Protects brand reputation |

| Communication | Can you understand each other clearly? | Prevents costly errors |

| MOQs | Do their minimums fit your order size? | Affects inventory & cash flow |

| Pricing & Value | Is the price fair for the quality/service? | Balances cost and brand standards |

| Reliability | Will they deliver on time? | Crucial for launch dates, sales |

| Compliance | Do they meet ethical/legal standards? | Important for brand values, market access |

Conclusion

Finding top custom streetwear manufacturers in China means looking past simple lists. Focus on partners specializing in streetwear, offering deep customization, ensuring quality, communicating clearly, and fitting your business model.